General

The Dickow HZS/HZSA pumps are designed with volatile liquids in mind. These multi-stage centrifugal mechanically sealed pumps have one side channel impeller that allows for the handling of entrained vapors reducing the likelihood of vapor lock. The HZS top-suction top-discharge design offers self-priming capabilities once the pump is initially primed. This design makes the pump ideal for tanker truck, rail car, or underground tank unloading applications, since the HZS can purge the suction line of air and vapor. The HZS/HZSA pumps can offer flows up to 600 m3/hr (2,460 gpm) and differential heads up to 500 m (1,640 ft). The maximum operating temperature is 100 °C (212 °F) and the maximum operating pressure is 16 bar (232 psi).

|

N/A

Construction |

|

N/A

Materials |

|

N/A

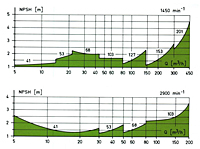

NPSH-Values |

|

N/A

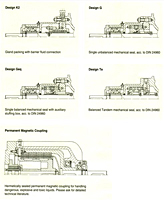

Shaft sealing systems |