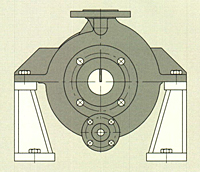

The DICKOW-pumps, type NCR, are heavy duty centrifugal pumps for petroleum, petrochemical and natural gas industries. The pumps are designed and manufactured according to API 610, 10th ed. / ISO 13709. This international standard specifies requirements for centrifugal pumps used in the above industries. The standard does not refer to any outline dimensions of the pumps.

APPLICATIONS

The performance range of the NCR-pumps is subdivided such that acceptable efficiencies can be achieved for all service conditions. The maximum capacity goes up to 700 m3/h (3100 USgpm). Differential head up to 145 mLC (480 ft) at 2900 rpm and 220 mLC (660 ft) at 3500 rpm.

With a wide selection of materials and the possibility to install all shaft sealing systems according to API 682, DICKOW-NCR-pumps are suitable to convey nearly all kinds of liquids which are usual in the above mentioned industries. E.g. acids, lyes, chlorinated hydrocarbons, heat transfer media (HTM), all kinds of hydrocarbon fuels, liquid sulphur, melted plastics, bitumen etc.

If the application requires sealless pumps, consider also our magnetic coupled PRM-pumps according to API 685.

Maximum Capacity (Flow Rate) |

N/A 700 m³/h (3100 USgpm) |

Differential Head |

N/A 145 mLC (480 ft) at 2900 prm and 220 mLC (660 ft) at 3500 rpm |

Maximum Temperature |

N/A 330°C (620°F) |

Maximum Allowable Working Pressure |

N/A 24 bar (350 psi) |

Bearing Information |

N/A

Bearings |

|

N/A

Design |

|

N/A

Pump shaft |

|

N/A

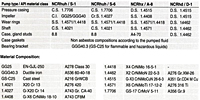

Pump material |